Table of Content

In today’s society, led strips are widely used in modern life. Given the increase in outdoor usage scenarios, the waterproof level of light strips has also been enhanced accordingly.

In this guide, I will show you the definition, types, common waterproof materials, waterproof structure, waterproof IP comparison, selections and related questions about waterproof led strips.

1. LED Strip Waterproof IP Rating Overview

(1) Definition

The waterproof rating of LED strips refers to their standardized classification of protection against external moisture and dust ingress, typically denoted by the IP (Ingress Protection) rating.

An IP rating consists of two digits, indicating protection against solid particles and liquids, respectively.

(2) Structure of IP Ratings

First Digit (Solid Particle Protection): Ranges from 0 to 6, indicating resistance to solids (e.g., dust, debris).

Second Digit (Liquid Protection): Ranges from 0 to 9, indicating resistance to liquids (e.g., drips, sprays, immersion).

2. LED Strip Waterproof IP Rating Types

(1) Non-Waterproof LED Strips (IP20/IP33)

Description: Designed for indoor use in dry environments with no exposure to moisture.

Features:

Minimal or no protective coating.

Lightweight and cost-effective.

Applications: Home interiors, cabinets, or decorative lighting.

(2) Drip-Proof LED Strips (IP54/IP55)

Description: Protected against low-pressure water jets and dust.

Construction:

Surface Coating: Silicone or epoxy resin is applied to the PCB to seal components.

Limitations: Not fully submersible; suitable for damp areas like kitchens or bathrooms.

Applications: Outdoor signage (covered areas), indoor humid zones.

(3) Water-Resistant LED Strips (IP65)

Description: Resistant to dust and water jets from any direction.

Construction:

Semi-Casing: A silicone or PVC tube partially encases the strip, leaving gaps for heat dissipation.

Material: Often uses epoxy resin for flexibility and moderate waterproofing.

Applications: Outdoor installations (e.g., garden paths, patios) with indirect rain exposure.

(4) Fully Waterproof LED Strips (IP67/IP68)

Description: Fully sealed against dust and prolonged submersion.

Construction:

Full Encapsulation: The strip is entirely enclosed in a silicone or PVC sleeve.

Subtypes:

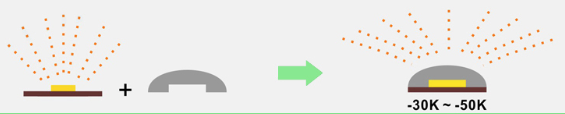

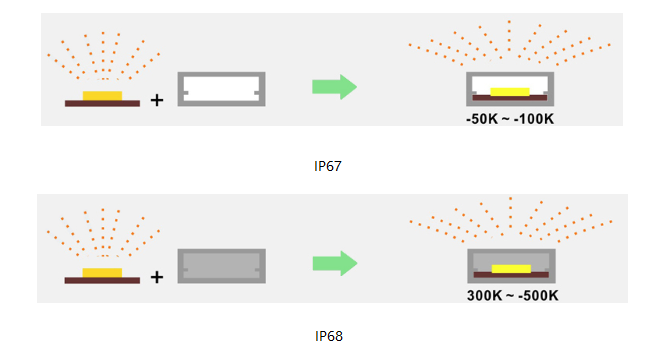

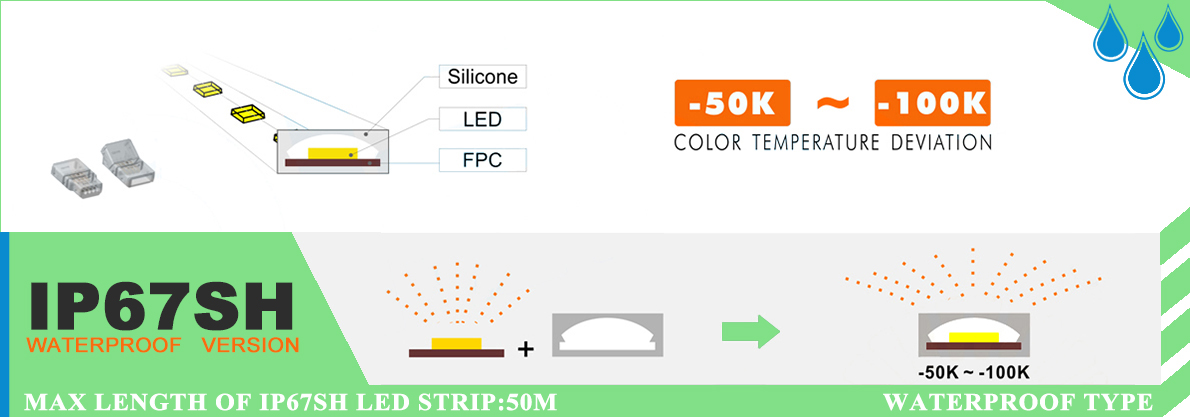

Sleeve-Only (IP67): Submersible up to 1 meter for 30 minutes. Basic waterproofing with a hollow tube (less durable).

Potting (IP68): Fully submersible (depth varies by manufacturer, typically ≥1.5 meters). Silicone or epoxy resin is injected into the sleeve for complete sealing, offering superior moisture resistance but reduced flexibility 139.

Applications: Submerged lighting (e.g., pools, fountains), harsh outdoor environments.

3. Common materials used in waterproof LED strip

(1) Epoxy Resin / PU Potting Compounds (Primarily IP65):

It is low cost but prone to yellowing after 2–3 years outdoors. Reduced flexibility post-curing makes them suitable for short-term outdoor or humid indoor applications.

(2) Silicone-Based Systems:

Coating (IP65): A thin silicone layer coats the PCB, offering UV resistance and flexibility for curved installations (e.g., furniture edges).

Sleeve (IP67): Thick-walled silicone tubing provides physical protection, wear resistance, and tolerance to minor impacts (e.g., under garden pavers).

Potting Compound (IP68): High-grade silicone filler withstands extreme temperatures (-45°C to 200°C) and seawater corrosion, ideal for deep-sea or high-temperature industrial environments.

(3) Nano-Coating (e.g., Parylene) (IP65+):

A 10–100μm ultra-thin film formed via chemical vapor deposition (CVD) penetrates micro-gaps (e.g., solder joints) without impeding heat dissipation. Used in precision equipment like marine lighting.

4. Waterproof LED strip structure

(1) Heat Shrink Tubing Sealing:

Heat-shrink tubing wraps connection points and is paired with silicone sealant at ends to achieve IP65+ protection. Commonly used in DIY outdoor wiring.

(2) Waterproof Connectors:

Molded silicone connectors with O-rings provide IP67-rated dust and water resistance, eliminating risks of exposed solder joints. Suited for scenarios requiring frequent disassembly.

(3) Aluminum Waterproof Channels:

Extruded aluminum profiles integrated with silicone gaskets deliver dual IP67 protection and heat dissipation. The preferred choice for high-power LED strips.

5. Key Differences between IP67 and IP68 LED Strips

The distinction between IP67 and IP68 LED strips lies in their water immersion resistance and application-specific durability. Both share a dustproof rating (IP6X), but their liquid protection capabilities differ significantly.

(1) Water Immersion Resistance

| IP Rating | Protection Level | Test Conditions |

| IP67 | Temporary immersion in water (up to 1 meter depth) for 30 minutes. | Submerged in 1m of water for 30 minutes. |

| IP68 | Continuous / prolonged immersion in water (exceeding 1 meter depth) as specified by the manufacturer. | Depth and duration vary by product (e.g., 2m for 24 hours or 3m indefinitely). |

(2) Construction and Sealing

IP67:

Uses silicone sleeves or epoxy resin potting to create a watertight seal.

Suitable for environments with occasional submersion (e.g., garden ponds, outdoor fountains).

IP68:

Employs high-grade potting compounds (e.g., silicone gel) for full encapsulation.

Designed for permanent underwater use (e.g., pools, aquariums, marine lighting).

(3) Application Scenarios

(4) Durability and Cost

IP67:

Lower cost (20–30% cheaper than IP68).

Limited to intermittent water exposure; prolonged submersion risks seal failure.

IP68:

Higher upfront cost but longer lifespan in extreme conditions.

Resists saltwater, chemicals, and high-pressure cleaning.

(5) Installation Considerations

IP67:

Avoid direct high-pressure water jets (e.g., power washers).

Ensure connectors are sealed with silicone grease.

IP68:

Verify manufacturer-defined immersion limits (e.g., depth/duration).

Use corrosion-resistant materials (e.g., stainless steel mounts) for saltwater applications.

6. Guidelines for Selecting IP Ratings

(1) Dry Indoor Environments (e.g., bedrooms, offices):

IP20/IP33 (cost-effective, no waterproofing needed).

(2) Humid Indoor Areas (e.g., kitchens, bathrooms):

IP54/IP55 (resists splashes and steam).

(3) Semi-Protected Outdoor Areas (e.g., balconies, covered walkways):

IP65 (resists rainwater splashes, avoids direct exposure).

(4) Unprotected/Extreme Outdoor Environments (e.g., gardens, building facades):

IP67/IP68 (withstands heavy rain, hail, or prolonged moisture).

(5) Submerged or High-Pressure Settings (e.g., pools, industrial facilities):

IP68 (fully sealed, resistant to high-pressure impacts).

7. Silicone glue encapsulated waterproof LED strips connection

8. Waterproof LED strips FAQS

9. Summary

Waterproof light strips are poised for sustained growth, driven by technological advancements, urbanization, and policy support. While challenges like cost and competition persist, innovation in materials and smart technologies will unlock new applications in smart cities, cultural tourism, and underwater environments. Companies that prioritize R&D, sustainability, and niche market strategies are likely to lead this dynamic industry.